Abstract

PDMS is a popular material for making droplets, but its properties (porosity, low thermal conductivity, autofluorescence, lack of rigidity) make it less than ideal for incubating droplets. We developed silicon chambers to incubate ~300,000 droplets in a precisely controlled temperature gradient. The chamber draws from the strength of Silicon (mechanical robustness, airtightness, thermal conductivity and optical reflectivity) while avoiding its drawbacks (complexity and cost of fabrication, bonding and chip-to-world connection).

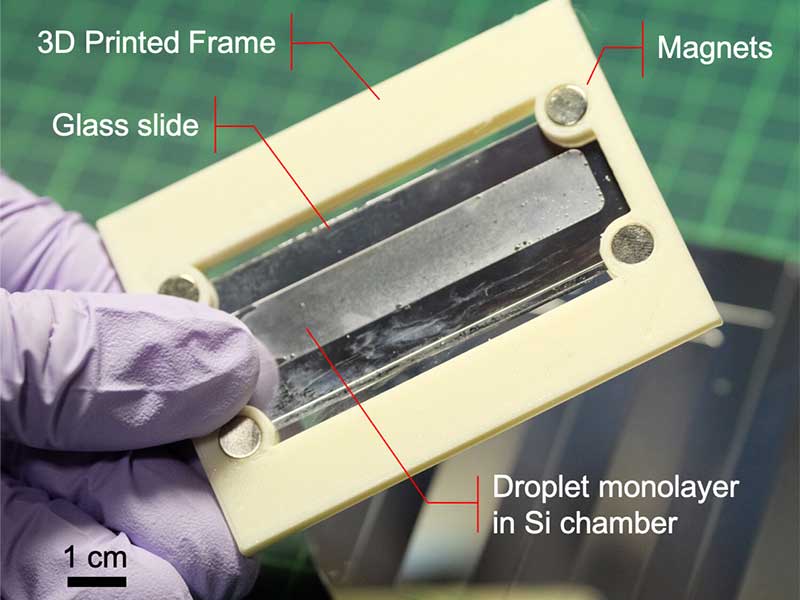

The chambers are fabricated by etching a rectangular chamber (~1 cm × 6 cm) with a depth (of ~50 μm) that prevents bilayering. After etching, the chambers are first coated with a thin layer of Al (to enhance their optical reflectivity) and then with a layer of CYTOP to render their surface hydrophobic. We fill the chamber with a "self-closing" strategy that eschews the challenge of connecting a chip to the outside world. Briefly, the emulsion is gently spread along in the chamber, and enclosed by simultaneously sliding a coverslip on top. The thin layer of oil and surfactant tightly seals the chamber for at least a few days. We then slide the chamber in a 3D-printed magnetic frame and fit it in our observation setup.

Sillicon chamber filled with a monolayer of droplets, encased into a 3D printed frame

Sillicon chamber filled with a monolayer of droplets, encased into a 3D printed frame

Collaboration

- Rondelez Lab, ESPCI

- Fujita Lab, IIS, University of Tokyo

Sponsor

- CNRS